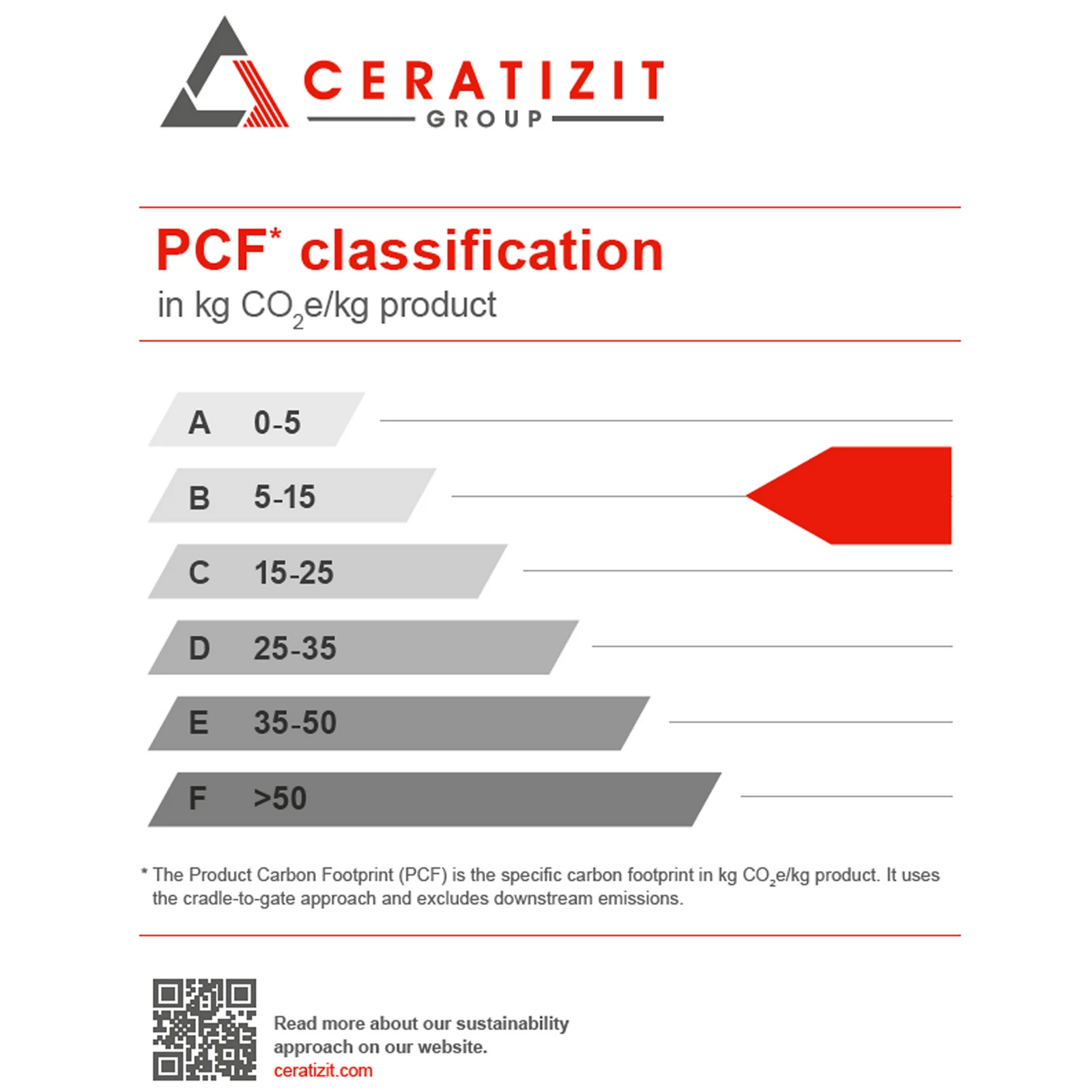

Like well-known rating systems, customers should be able to grasp and evaluate the footprint of a product at a glance. The length of the bars makes it possible to intuitively grasp the level of emissions. The bars differ in their grey gradation; colouring was deliberately omitted to avoid any associations with other scales. The alphabetical PCF (Product Carbon Footprint) classification can be integrated into any product data sheet or sales document. From mid-September 2023, the PCF classification will be visible to all customers who purchase products with a PCF classification.

The PCF is then calculated from the CO2 footprints of the raw materials plus the CO2 footprints of the production processes involved, each weighted with the efficiency factors from the raw material to the finished product. The result is the CO2 footprint per kilogram of this particular product. The calculation approach is in line with the ISO 14067:2018 standard and has been critically reviewed by a third party, denkstatt, a member of Inogen - Environmental Alliance.

We have illustrated how this works in our video: